Fibre Cement Boards for Tough, Long Lasting Exterior Wall Systems

The Exterior Shell is the most important factor of protection to ensure that the various parts of the building, foundation, frame, Interior Assets remain intact from the weather conditions.

Nature Provides the Ingredients

Using water, sand, cement and natural cellulose fibres, combined with SHERA’s unique autoclave treatment during the curing process results in a very strong and durable Fibre Cement composite material which is extremely light weight for its strength!

Results that Rock!

The perfect sheathing material for exterior walls, SHERA board is easy to maintain, tough, moisture and fire resistant.

SHERA board is a unique fibre cement composite consisting of natural fibres bonded tightly in a high-grade silicate structure.

The result is a material that is highly durable, flexible, water resistant, fire proof, resistant to insects and chemical corrosion with a neutral PH.

SHERA boards are also highly workable and can be used in many building applications by architects, project developers and home owners.

Anatomy of SHERA Boards

.gif)

Compatible with Any Structural Frame Type

SHERA Exterior Wall Solutions can be combined with any structural frame type.

Compatible with Any Final Finish

SHERA Wall solutions can be combined with any final appearance application.

Choose the thickness of the exterior wall 100mm or 200mm to serve thermal insulation needs.

Choose the thickness of the exterior wall 100mm or 200mm as architectural preference and structural needs.

Choose the Framing Solution for the required wind pressure resistance.

Thermal Insulation

A 100mm or 200mm exterior wall can be the choice for any framing solution. The wall performance in terms of thermal insulation will be affected by the thickness of the insulation in the walls’ cavity as below:

Architectural Preference & Structural Needs

A 100mm or 200mm exterior wall can be the choice for any framing solution. However the thickness of the exterior wall can be used to hide structural columns or allow the cantilever distance needed to adjust the final exterior surface without the need for extra wall support clips. Furthermore it provides the capability to create wall recessed areas for creating a specific architectural design.

Framing and Wind Resistance

The walls’ structural design in terms of spacing and profiles used will determine the walls’ resistance to wind pressure. The following table is a general guide but the advice of the projects’ engineer is needed since various conditions as specific local requirements, building height, architectural design and other surrounding environment will define the requirements.

Framing - Additional Recommendations & Guidelines

We recommend the thickness of the steel studs to be at least 0.7mm thick and have a flange of at least 50mm to allow proper board fixing. If local availability of profiles does not allow that, we recommend using a back to back double stud every 1200mm at the connection of boards.

On door openings or any other cavity you do need a double stud (see picture), regardless of the flange width, which will offer a hidden control joint. The board should have a vertical joint at the side of the cavity (as picture) and unlike other weak low density sheathing materials.

In the case of a wall without any openings, a vertical control joint is recommended every 8 linear meters.

All Board edges should be supported by frame. If the wall is taller than the height of the board, there must be a horizontal frame support of at least 50mm wide to connect the next at height board and allow for the proper horizontal joint treatment.

SHERA Board Technical Specifications

| Physical Properties | |

|---|---|

| Thickness Tolerance | +6% |

| Density | 1350 + 50 kg/m3 |

| Modulus of Rupture | > 7 MPa (Wet) |

| Modulus of Elasticity | 3000 MPa (Wet) |

| Water Absorption | < 35% |

| Moisture Content | < 15% |

| Water Tightness | Pass |

| pH Value | 7-8 |

| Thermal Conductivity | 0.15 W/m.K |

| Acoustic Insulation | STC = 30 dB (6 mm single board) STC = 50 - 60 dB (10 mm composite wall) |

| Moisture Movement | + 0.04% |

| Length Change Due to Water Absorption | < 0.10% |

| Fire Resistance Properties | |

| Ignitibility | Pass |

| Fire Propagaton Index | I = 0.4 |

| Surface Spread of Flame | Class 1 |

| Reaction to Fire Classification | A2 - s1 d0 |

| Combustibility | Non-Combustible |

| Durability Properties | |

| Freeze / Thaw Resistance | Pass |

| Warm Water Resistance | Pass |

| Heat / Rain Resistance | Pass |

| Soak / Dry Resistance | Pass |

SHERA Boards are available in thicknesses of 4mm, 6mm, 8mm, 9mm, 10mm, 12mm, 15mm and 18mm for various applications.

SHERA Boards can provide the architectural freedom for the design of curved walls

Fixing SHERA Board on a Framed Wall Structure

Having decided the thickness of the wall and the profiles to be used (steel or timber), there are a few points that require your attention for the best possible performance.

Special attention is required to the fastening distance needed from the board edges and are shown at the below diagram.

Boards are installed portrait to have a vertical joint every 1200mm max.

The number of screws to fix the Shera Board on to the wall structure as standard are as shown on the adjacent diagram. For high demand wind resistance walls they should be done according to the wind resistance table above. (See Framing section).

A gap of 3-5 mm should be maintained between board joints for filling with SHERA PU joints sealant.

(See method of application, below at the Water Sealing section).

Screws and Tools Recommended

Water Sealing Exterior Wall Connection Joints

Primer for dust.

SHERA Cement Bonding.

Apply SHERA Cement bonding agent over the 3-5mm joint gap between the SHERA boards.

The bonding agent provides good bonding for the SHERA PU25 Sealant and SHERA boards and helps to seal the construction dust which might reduce the adhesion of the sealant.

Apply only once and leave for 10-20 minutes to dry.

APPLY PU25 SEALANT

Gap 3- 5 mm between boards.

Cover the edge of the board with easily removable masking tape.

Fill the gap with sealant PU25 in an upward motion until it is completely full.

Immediately remove the masking tape after completing the sealant application.

PU25 SEALANT

One component elastic polyurethane sealant, self-cured in contact with air and humidity, paintable.

Usage: exterior, wet areas.

Accessories and Extra Tools Needed

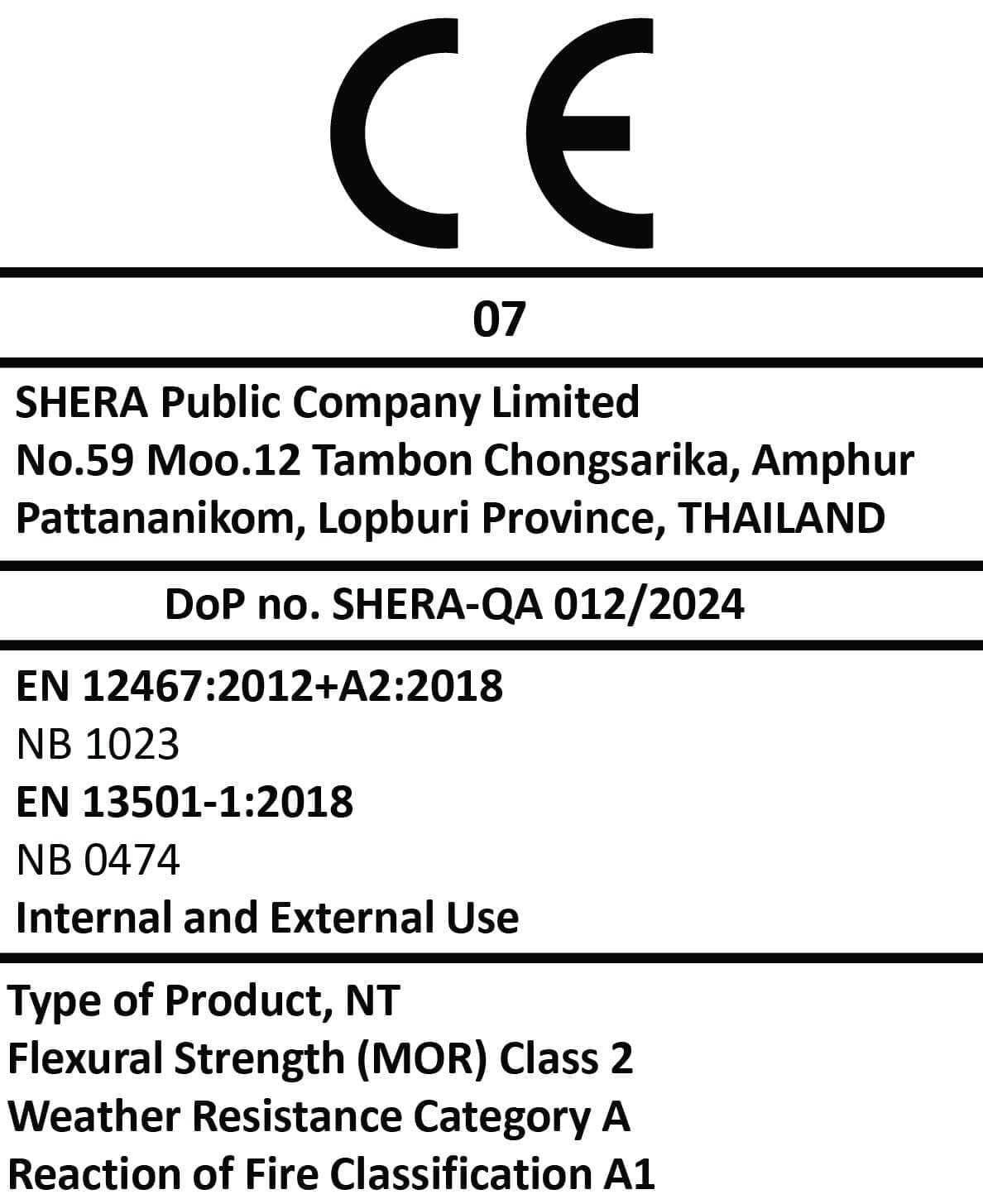

Standards and Certifications

- CE Declaration

- Declaration of Performance

- Environmental

- Fire

- Impact

- ISO

- Quality

- Acoustic Insulation

- Thermal Insulation

- Miscellaneous